After some gales that exceeded predicted wind speeds, we got our chance to fix the wind generator. Waiting for the opportunity was particularly harrowing because we couldn’t brake it. We had to leave it to freewheel through the high winds, unable to tell if this would compound the damage that already occurred or not.

Friday’s forecast called for the wind to switch from south to north. We might have a few hours when the wind could be calm enough to try the inspections the manufacturer’s support person suggested. However, the north wind was predicted to build to 35 knots by afternoon.

In other words, we had a test coming. A timed test, in which we didn’t know how much time we would have—we could only attack the problem and hope to be finished before time ran out.

At first light yesterday, I stepped outside to fetch the climbing ladder, into a snow shower. I set up the ladder anyway, hoping the weather would ease. By the time I was ready to ascend, the wind had died to a breeze, and we got busy.

I couldn’t decide which possibility to test first, some sort of fault at the two different wire connections on the tower, or the the stator wires in the voltage selection housing. The connections seemed sound, so instead of pulling them apart to make sure, I checked the voltage selection. The examination plate secures with two hex screws, which had fused in the maritime climate.

We conferred, and decided that we should remove the generator blades. If we had time, we could lower the tower, but if not, at least the turbine wouldn’t freewheel in the coming gale. We would surrender the possibility of charging on the one remaining circuit that survived the trouble. But, fixing the machine ourselves, or sending it in for warranty repair both made lowering the tower necessary.

When we installed this generator, I built a cantilevered tower based on the original generator’s pole, and an additional length of pipe. We always knew that we could lower the generator, but never had until Friday. I’d completely forgotten how easy we’d made it! The hardest part proved to be climbing the tower to remove the clamps that hold the two towers together and hanging the double block system. After that, Michelle lowered it herself without raising a sweat.

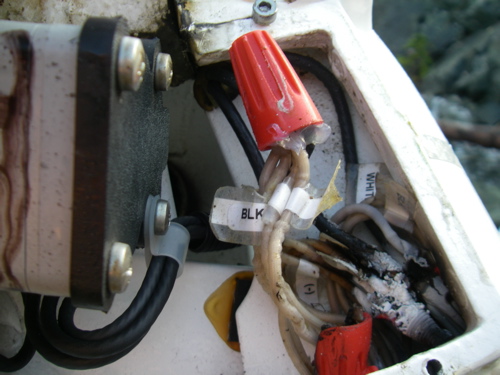

Once on the ground, I managed to break the hex screws free. Inside we found two of the three sets of stator wires fried. Carbon from the burning stained the housing horribly on the side of the generator that had faced away from the cabin most of the time. We had not seen how bad it was until we’d brought it down. It only worsened the staining from the “marine” lubricant in the furling shaft, which had flushed out in the first rain after mounting the generator. It had helped hold moisture and grime on the housing, making the “marine” paint bubble and blister, and corrode the metal.

I cut the wires, stripped a new length on each, buffed them up with sandpaper, and made new connections. Michelle scrubbed the stains off as well as she could. We re-wrapped some of the wiring, and adjusted the furling shaft fastenings so that it hopefully won’t stick.

During this process, the wind died, the sun came out, and we enjoyed the gentlest, balmiest January day we could ask for. As we brought the tower down, I’d begun an extensive mental list of tasks to complete while we waited—for another calm day, if not for the manufactuer to repair and return the generator. I identified items to check, build, improve, or replace in the meantime. Suddenly, we abandoned all of that for the chance to get the tower back up before the north wind started.

We had the tower raised, and everything in order before it began to get dark. Then we waited for the wind. The forecast had changed while we worked; light southerly wind continuing till turning north and reaching 35 knots late. We had a long, suspensful wait before we started gettting a charge, at 2:00 am, and could confirm that the voltage levels were good. The generator is fixed!

Of course, there’s still the possibility this could happen again. We’re pretty sure the wires burned out when the machine couldn’t furl in high winds, but we will likely never know for certain.

As you might imagine, I derived a lot of satisfaction from this success. Beyond the obvious relief of not having to ship it off to be fixed, and the pleasure of a job well done, I learned a few very valuable lessons.

Like most other Americans, if something goes wrong, I’d really rather someone else fixed it. Our warranty lasts another year. Even though it would cost us considerably to mail it away, we could have simply sent it in for repair. It would be returned in working order, and we’d never be told what had gone wrong. It would be easy not to care, as long as it got fixed.

Instead, with guidance from manuals and support, we found the trouble and fixed it. I remembered that these machines aren’t so very mysterious. People made them, people can fix them. When the warranty expires, it will be up to us. This experience will embolden me to fix the problem myself. That’s satisfying!

SUPER – Glad your back in business – great to be able to fix things yourself – That cantiliver setup is really neat – Wish I had something like that on a sailboat I had – The wife and I never could get the mast stepped by ourselves. Usually ended in no sailing and not a happy camper – Today has been a good day for the both of us – were back in the dryer business – several trips under the house – not good for a couple of old men and my friend Bob being an electrician and were good to go – Have a good day.

Excellent, things are looking up for the little guy!

Great!